In 2003 I began a two part documentary photography project featuring the McGregor Socks knitting mill on Spadina Avenue, and the Korex soap and detergent works in the lower Don Valley. Both plants had long been part of downtown Toronto’s industrial sector, but each faced an uncertain future. The McGregor factory, the subject of the photo series shown below, was the last large employer in Toronto’s fading garment district.

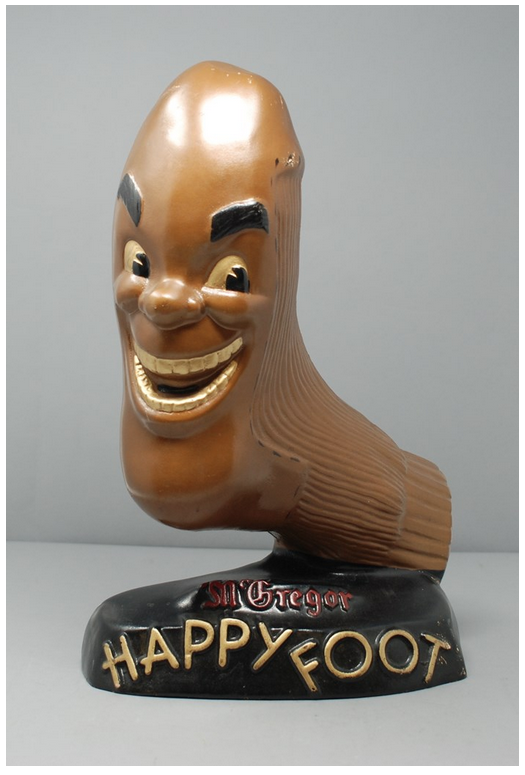

My familiarity with McGregor Socks as a brand dates from the 1960s, when I started wearing the company’s best-known product, the Happy Foot. This was a cotton sock with a fleecy padded sole that had been in production since 1937. The company had come up with a unique mascot for the Happy Foot model, a sculptural bust of a foot with a ridiculously happy cartoon face represented on its sole.

In 1984, I had contributed photos to Rosemary Donegan’s exhibition “Spadina Avenue: A Photohistory” at the artist-run gallery, A Space. The 1986 book based on the exhibition, “Spadina Avenue,” included photos of workers at the McGregor factory taken by the photojournalist Vincenzo Pietropaolo. By 2002, I could see the need for a more complete photographic record of this historically important industrial workplace.

The McGregor factory and offices were housed in two adjoining structures representing successive generations of industrial architecture. The three-storey brick and timber Gale Building at 30 Spadina Avenue dates from 1905. McGregor moved from its original location at 49 Bathurst Street to 30 Spadina about 1950, replacing the previous tenants, J. H. McNairn, Paper Manufacturer, and the Dominion Paper Box Company.

Until 1960, the Gale Building was overshadowed by its institutional neighbour on Wellington Street West, a domed and turreted Baroque horror that had been the first home of Loretto Abbey, a private Catholic girls’ school. Shortly before the school complex was demolished, McGregor built 401 Wellington West, a five-storey reinforced concrete extension to the factory, on land that had formerly been a corner of the school campus.

During the limited time I was allowed to spend inside the McGregor plant, I tried to strike a balance between learning about the production process and documenting as much of it as possible. I also tried give some sense of the social life of the plant, which complimented the steady tempo of the work.

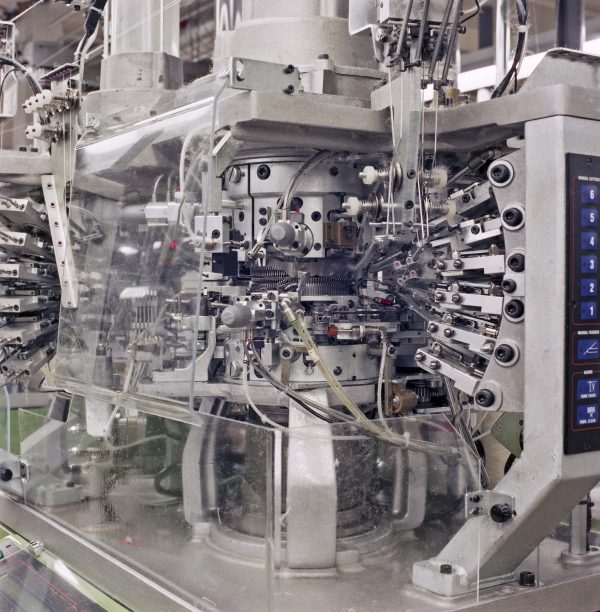

Industrial sock knitting is a mechanical marvel that has now been adapted to digital programming. Anyone familiar with artisanal knitting machines will recognize the basic design principles behind the industrial machines shown in my photos, but I was awed by their thorny technical complexity.

What most distinguishes a loft factory from a modern single-storey industrial unit is the amount of light that comes through the windows. Taken in early spring, my photos record the varied lighting in different parts of the McGregor plant, ranging from limpid daylight to flat, greenish light from fluorescent tubes.

McGregor still markets Happy Foot socks, but they are made offshore. Its Toronto plant closed in 2005, and the intact buildings are now occupied by Stantec, a multinational engineering firm. An information sheet posted by the new occupant states, “This heritage property, a defunct manufacturing facility built in 1905,* was ideal for reclamation and adaptive reuse.”

*As noted above, the two adjoining factory buildings were built at different times.

All photos © P. MacCallum, 2021 (petermaccallum.com)

For pop-up gallery view, click on a photo below.

Yarn supplies, basement warehouse, 2003.

Yarn supplies, basement warehouse, 2003.

Detail of yarn shipment, basement warehouse, 2003.

Detail of yarn shipment, basement warehouse, 2003.

Bales of yarn delivered to knitting department, 2003.

Bales of yarn delivered to knitting department, 2003.

Punch clock at employee entrance, 30 Spadina, 2003.

Punch clock at employee entrance, 30 Spadina, 2003.

Knitting machine aisle, looking toward lunchroom, 2003.

Knitting machine aisle, looking toward lunchroom, 2003.

Older knitting machinery in the newer section of the plant, 401 Wellington West, 2003.

Older knitting machinery in the newer section of the plant, 401 Wellington West, 2003.

Adjusting an older knitting machine, 2003.

Adjusting an older knitting machine, 2003.

Workers on break, 401 Wellington West, 2003.

Workers on break, 401 Wellington West, 2003.

Yarn creels, 30 Spadina, 2003.

Yarn creels, 30 Spadina, 2003.

Modern knitting machines, 30 Spadina, 2003.

Modern knitting machines, 30 Spadina, 2003.

Detail of double cylinder knitting head, 2003.

Detail of double cylinder knitting head, 2003.

Newly knitted socks, 2003.

Newly knitted socks, 2003.

Detail of ”greige” socks, 2003.

Detail of ”greige” socks, 2003.

Detail of employee lunch room, 2003.

Detail of employee lunch room, 2003.

View into mid-floor office, 2003.

View into mid-floor office, 2003.

Lab for preparing dyestuffs, 2003.

Lab for preparing dyestuffs, 2003.

Detail of dye samples, 2003.

Detail of dye samples, 2003.

Test machinery for dyestuffs, 2003.

Test machinery for dyestuffs, 2003.

Rotary drum dyeing machine, 2003.

Rotary drum dyeing machine, 2003.

Work station in boarding department, 2003.

Work station in boarding department, 2003.

Storage area for partially finished socks, 2003.

Storage area for partially finished socks, 2003.

Workers inspecting and matching socks, 2003.

Workers inspecting and matching socks, 2003.

Knitting machine mechanic, 2003.

Knitting machine mechanic, 2003.

Embroidering machines, 2003.

Embroidering machines, 2003.

Worker at the boarding machine, 2003.

Worker at the boarding machine, 2003.

Worker reversing socks using air suction tube, 2003.

Worker reversing socks using air suction tube, 2003.

Worker reversing socks after closing toes, 2003.

Worker reversing socks after closing toes, 2003.

Exterior view of former McGregor Socks factory, 30 Spadina Avenue and 401 Wellington Street West, 2021.

Exterior view of former McGregor Socks factory, 30 Spadina Avenue and 401 Wellington Street West, 2021.

The Happy Foot mascot.

The Happy Foot mascot.

2 comments

We had intex gloves made here in windsor.it employed many women and ran 24 hours a day.i used to stand in the doorway and watch.one day about a year later I could hear the machines so went to look inside.there were 3 people in there and everything looked the same with the same machines only they wee automated.wasnt long after that they moved to Mexico.it was nice knowing that the gloves I used at windsor assembly were being made right down the street and on the boxes of gloves said made in windsor Ontario.sad today that all that work although automated were still moved out of windsor to another country.and I am familiar with MacGregor socks and didn’t know they were made in toronto

My favourite brand, before medical necessity forced a change in recent years.